Auto parts

Lapsolite, as the market leader of the reinforced plastics industry, has a manufacturing division of components for reinforced plastic and lightweight plastics systems, directed to the assembly factories of cars and buses. According to our ability, we can offer being partners along with the manufacturing companies of vehicles and trucks.

In our portfolio of auto parts, Lapsolite offers the following possibilities:

- Elements for special and utilitarian purposes of vehicles

- Components and pre-assembled car units

- Bodies of panels for recreational vehicles

For the past 15 years, important automobile and urban bus lines manufacturers have been using our components, manufactured for interiors and exteriors. Lapsolite as a partner in development and supplier, offers from conceptualization to manufacture for their new designs as well as planning, project development, designing and making prototypes and tools for new parts. Mass production is carried out at our facilities in San Martín Texmelucan, Puebla; where each product, depending on the manufacturing process, is developed to be more cost effective and of the best quality.

OUR SERVICE

Our experience in manufacturing of automotive parts and close relationship with our clients on line assembly permits us to provide a timely service performing reliability analysis. It also allows us to contribute to the areas of engineering, manufacture, quality and production, potential design options and proposals of alternate materials with better results.

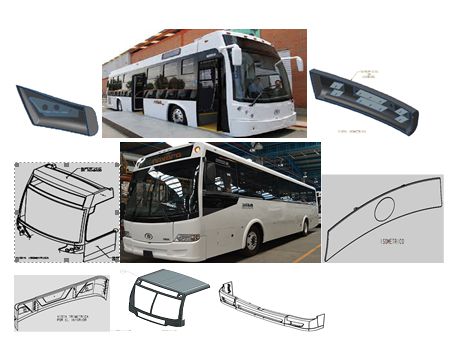

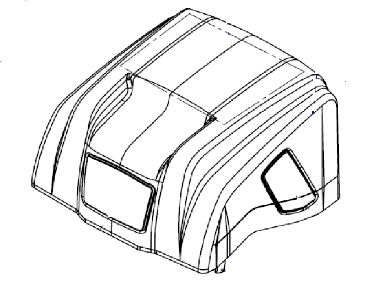

OUR PRODUCTS AND CUSTOMERS

DINA CAMIONES, S.A. DE C.V.

CIPSA INDUSTRIAS, S.A. DE C.V.

Lapsolite offers the following processes designed for different environments and applications:

Contact molding (manual laminate)

The manual lamination technique which falls into the group of molding by contact techniques is, without a doubt, the most well-known technical operation in the manufacture of parts with composite materials. The manufacturing capability of this type of work can be adapted according to the needs of each client, as we have sufficient personnel, machinery and tools, as well as an area of operations of more than 2,500 m2 exclusively for the area of auto parts.

RTM (resin transfer molding)

The trend towards the reduction of costs and the decrease in weight of reinforced plastics with fiber glass FRP for industries in aerospace, automotive and construction have promoted the development of new technologies for closed molding. It is worth indicating that the success of these materials lies in that they combine high mechanical performance, low weight, resistance to corrosion and the possibility of producing low volumes; although a high percentage of parts of GRP in Latin America are made through open molding systems, in the world, closed molding technology is being developed and used that offers higher productivity and quality as opposed to open molding. Along with closed molding technologies we should mention resin transfer molding (RTM, conventional), which implies greater investment in equipment and molds. However, there are some variants that involve more modest investments, such as with vacuum assisted resin transfer molding (RTM VACFLO), resin transfer molding infusion with a membrane and light resin transfer molding (light RTM).

Of particular importance and applicability to our environment is the process of light resin transfer molding (light RTM) that Lapsolite is perfecting day by day and which offers the following advantages in comparison to injection molding (manual laminate):

• Improvements in quality:

- You can obtain parts with a surface finish on both sides.

- Better reproducibility of the thickness of the pieces.

- Easy to mold complex structures, with thicknesses between 0.5 mm and 90 mm.

•Improvements in productivity:

- Lower production costs: some estimates made on the basis of a production of 15 units a day indicate that there can be annual savings in production costs of up to 40%, representing up to 10 times the value of a traditional mold.

- You can automate resulting in higher production speeds.

- Reduction in waste and reprocessing.

•Environmental improvements:

- Lower emissions of volatile components.

ENGLISH

ENGLISH